System Maintenance occurs every Friday.

Electrical

Chemical

Thermal

Mechanical

Structural

Radiation

Cross Discipline Effects

| Material | Density (g/cm3) | Hardness (kg/mm2) | Flexure Strength (KPSI) | Young's Modulus (GPa) | Thermal Exp. Coeff. (10-6/oK) at 23oC | Thermal Exp. Coeff. (10-6/oK) at 200oC | Specific Heat (J/gmoK) | Thermal Conductivity (W/cmoK) | Band Gap (eV) |

|---|---|---|---|---|---|---|---|---|---|

| ZnS | 4.08 | 230 | 14 | 74.5 | 6.8 | 7.7 | 0.468 | 0.17 | 3.58 |

| GaAs | 5.32 | 700 | 8 | 85.5 | 5.7 | 6.4 | 0.345 | 0.53 | 1.43 |

| GaP | 4.13 | 845 | 15 | 102.6 | 5.3 | 5.8 | 0.435 | 0.97 | 2.24 |

| Si | 2.33 | 1150 | 18.5 | 130.1 | 2.3 | 2.9 | 0.758 | 1.41 | 1.12 |

| Ge | 5.32 | 850 | 13.5 | 103.3 | 6.0 | Liquid | 0.310 | 0.60 | 0.67 |

| Diamond | 3.52 | 9000 | 427 | 1050 | 1.0 | 2.0 | 0.515 | 26.00 | 5.40 |

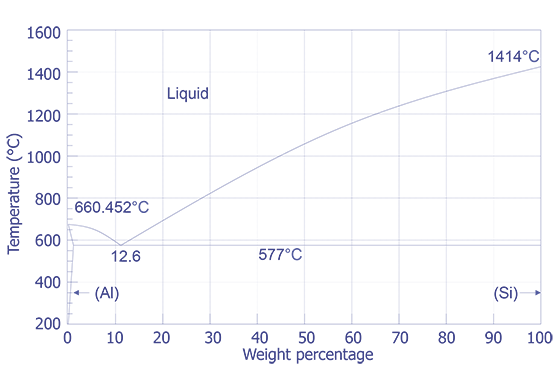

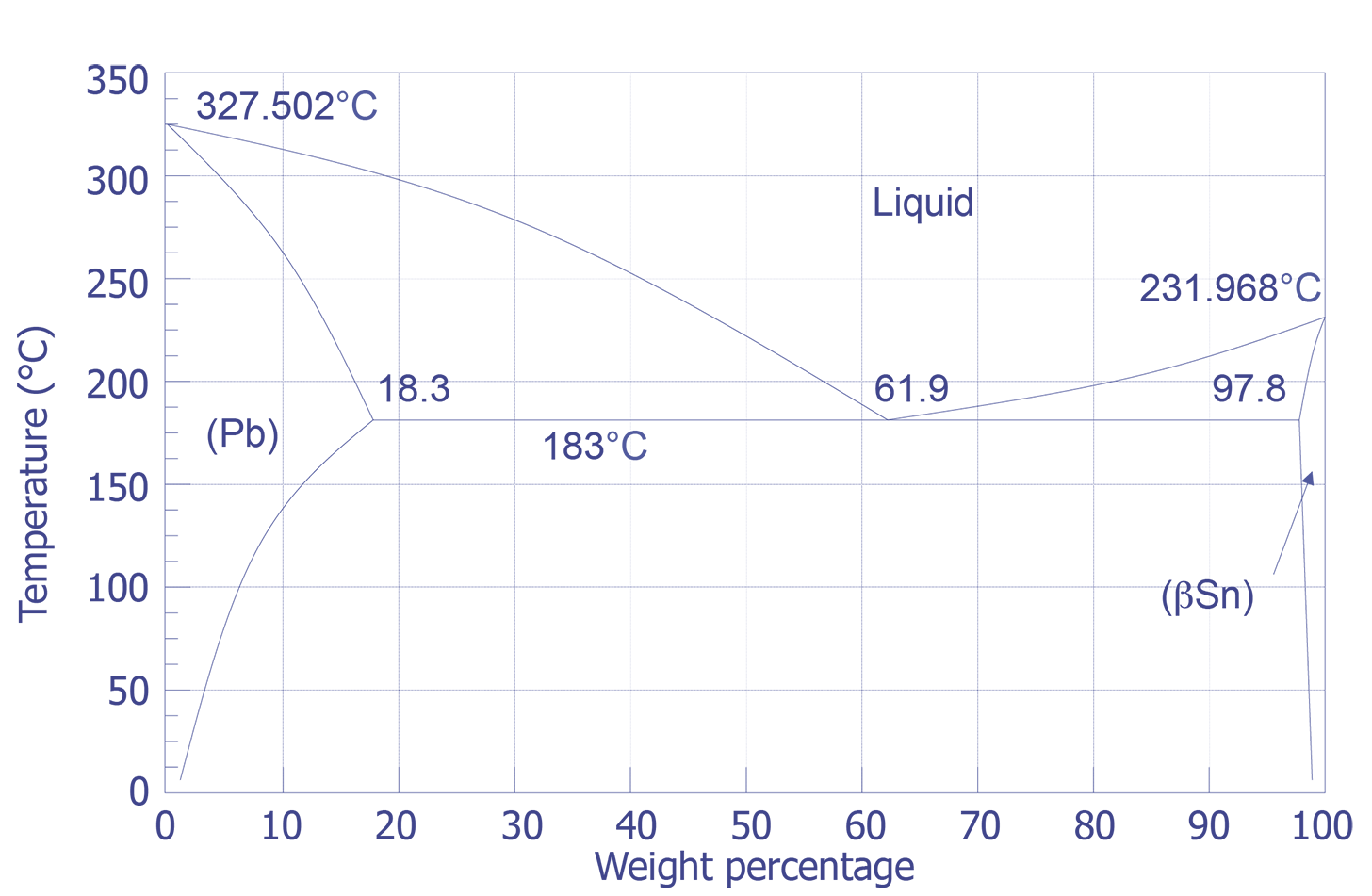

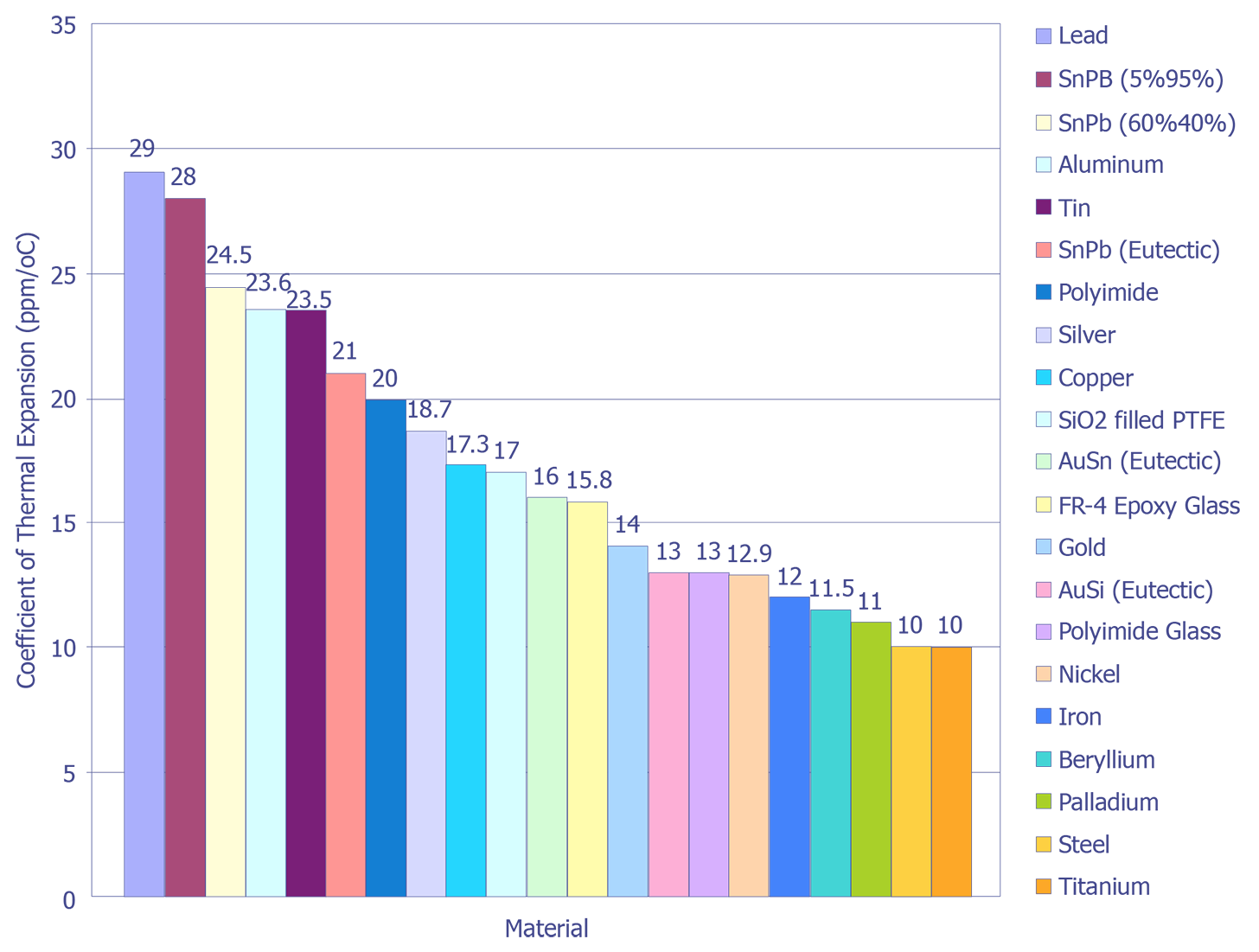

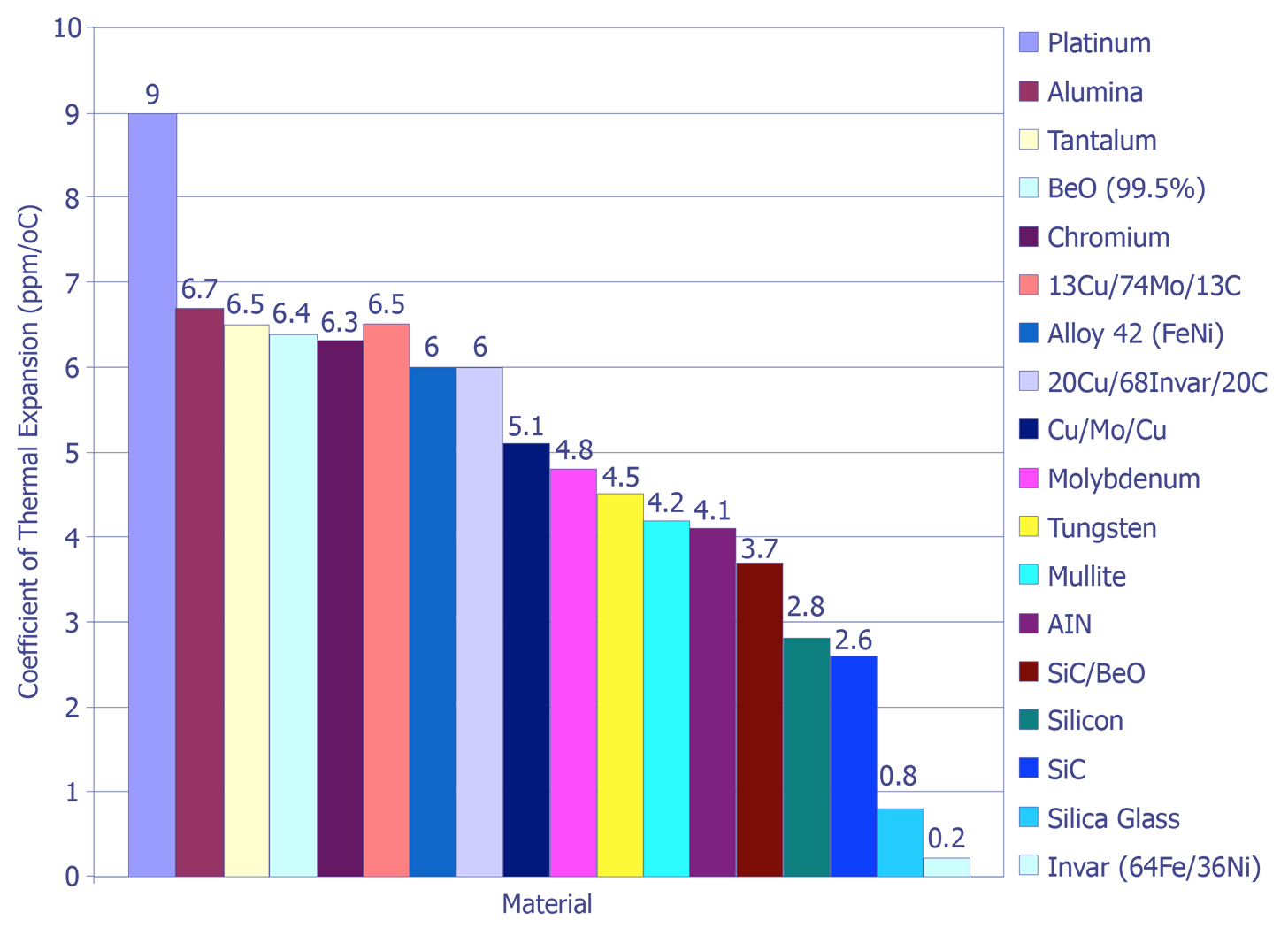

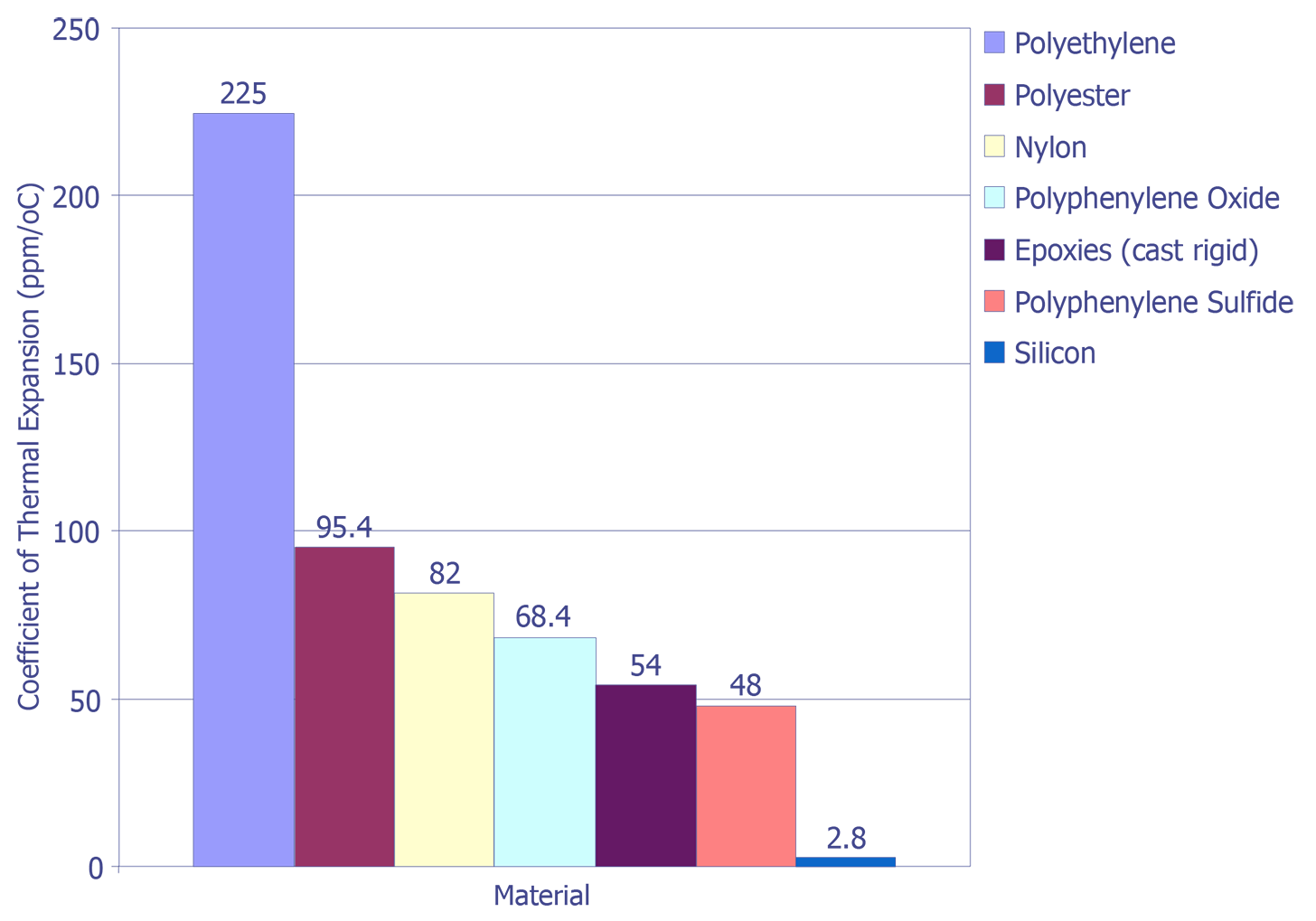

Thermal mismatch between materials is a major source of concern in microelectronics. A large mismatch in the coefficient of thermal expansion (TCE) between two bonded materials can result in large stresses and even cracking, delamination, or other types of failure. The following graphs show various TCE values for selected materials used in microelectronics processing and packaging. The larger the difference, the more concern there is for failure.

Coefficients of Thermal Expansion (Higher) for Selected Microcircuit Materials (see Figure 12)

Coefficients of Thermal Expansion (Lower and Polymers) for Selected Microcircuit Materials (see Figures 12 and 13)

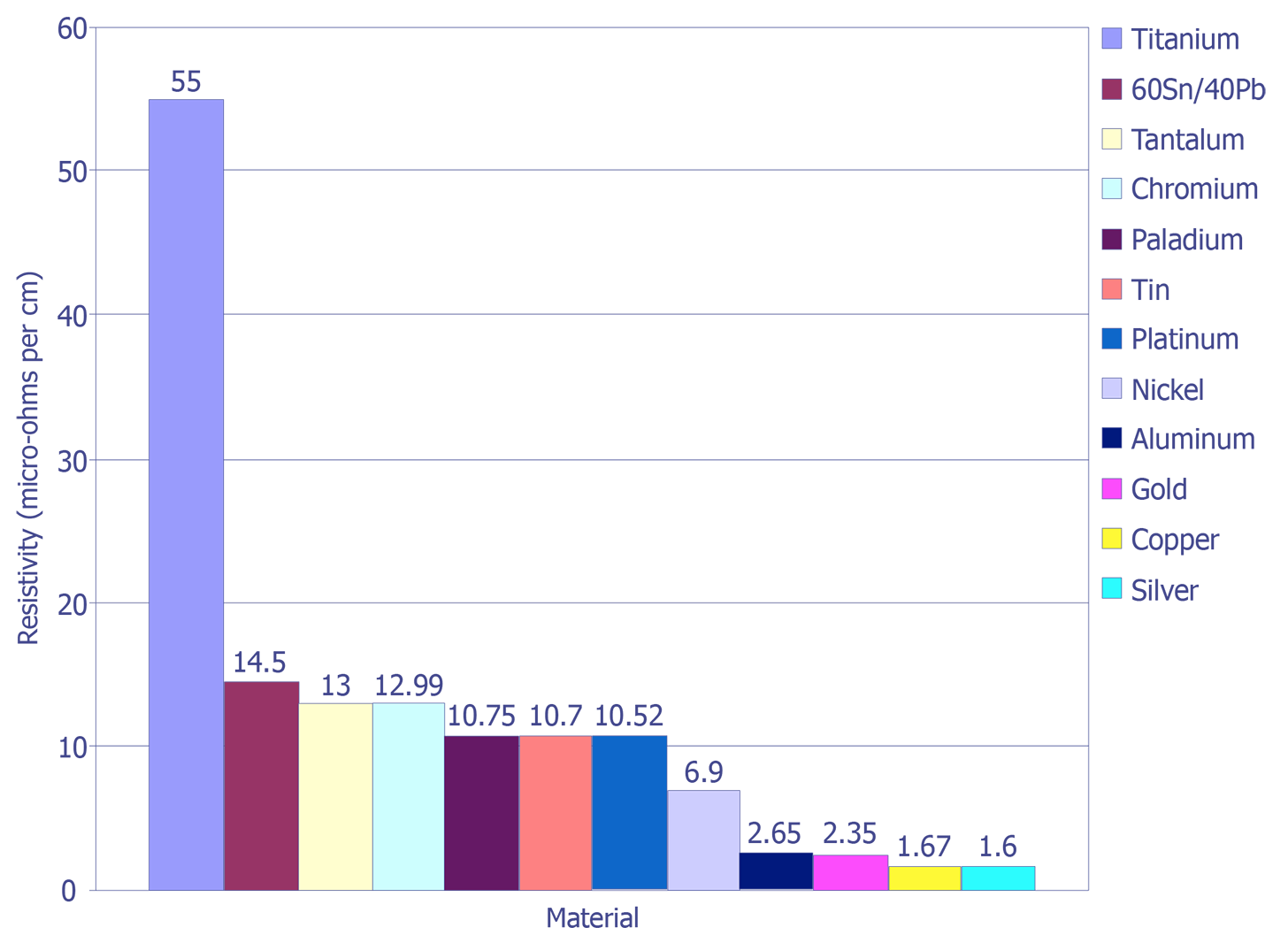

Metal systems used in microelectronics are typically tradeoffs between performance, reliability, ease of which to process, and contamination issues. Resistivity is typically an important factor when considering circuit performance. Below is a graph of resistivity for various metals used in microelectronic processing.

Resistivity Values for Various Metals (see Figure 14).

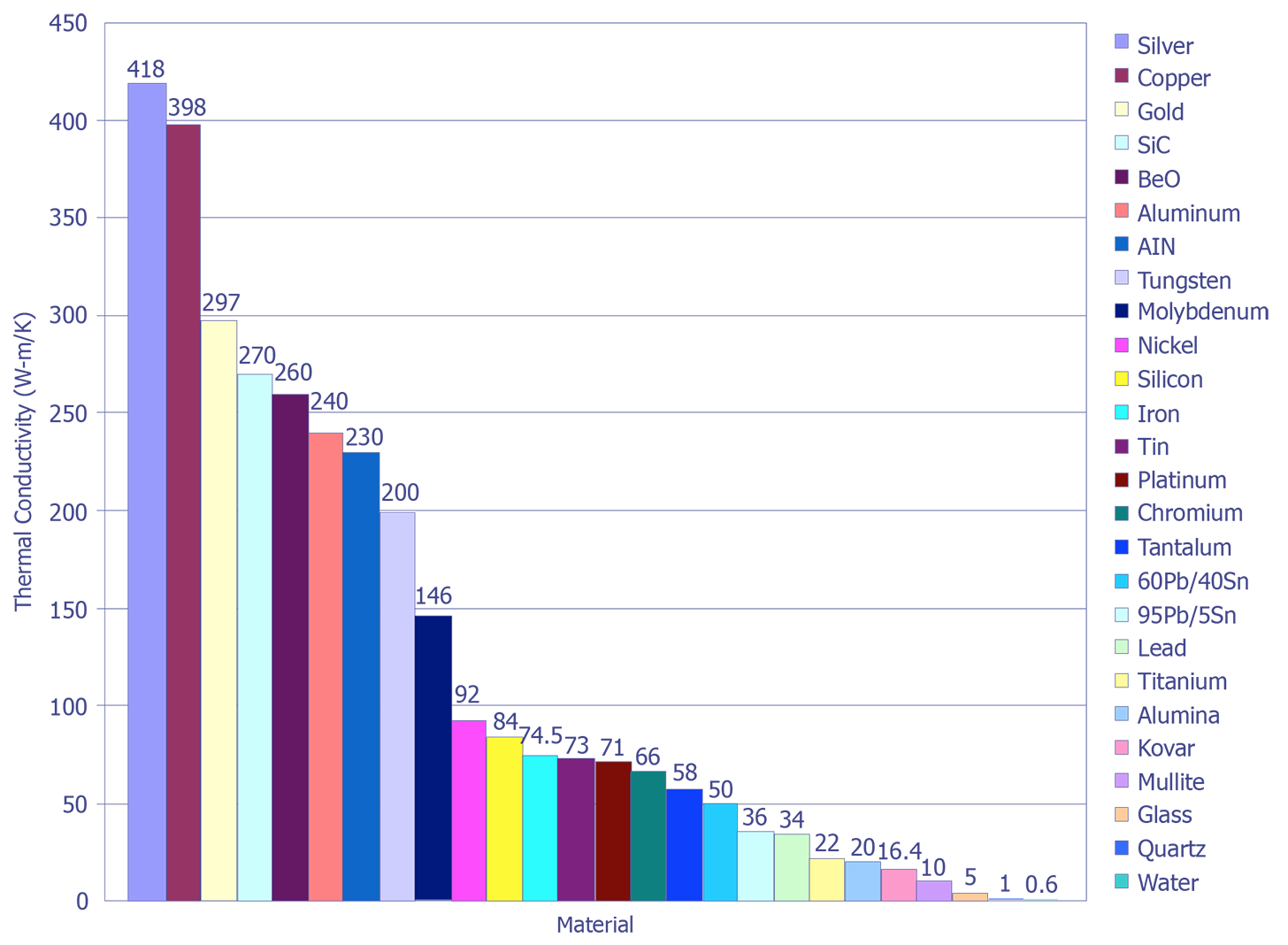

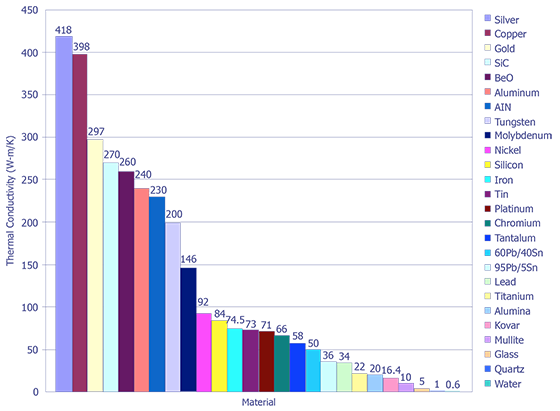

Thermal Conductivity Values for Various Metals (see Figure 15).